Rubber Bitumen Plant

Keyword:

Category:

Product Description

Intermittent rubber bitumen plant is a device developed for on-site small batch production. It can be applied to rubber gravel seals, bridge deck waterproofing, and other construction sites where a small amount of rubber bitumen is required. This set of equipment has the characteristics of convenient mobile site, rapid heating and accurate measurement.

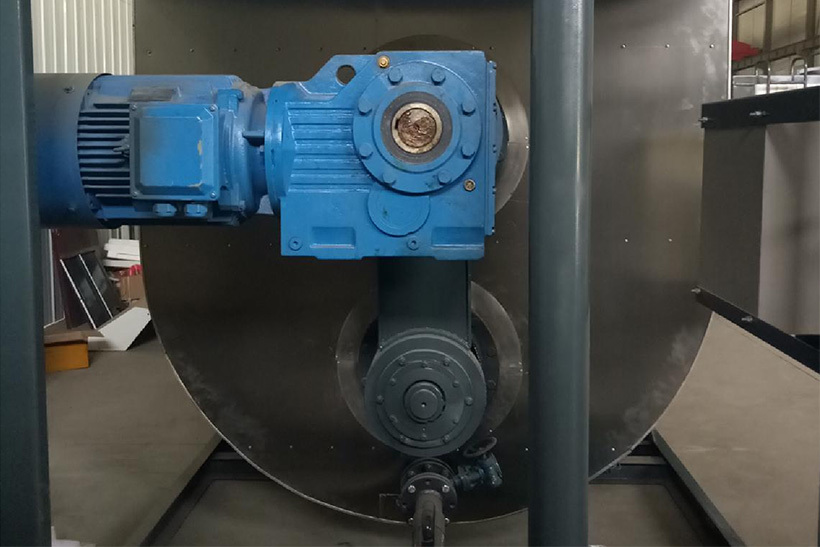

The equipment is mainly composed of five parts: heat-conducting oil boiler, heating mixing tank, rubber powder elevator, metering, and export pump group.

Features

1. The equipment is installed on the bracket as a whole for easy transportation.

2. The comparison between the heating system of the thermal oil boiler heating system and the direct heating of the burner.

A. High thermal efficiency and fuel saving.

B. The temperature of the heat-conducting oil pipe wall is 300-400℃ lower than that of the fire pipe to avoid the carbonization of the pitch close to the heat pipe.

C. The heat-conducting oil pipeline can be arranged at the bottom of the tank, so there is no dead angle for heating.

D. The heat-conducting oil furnace has expandability. (This set of equipment reserves the heat transfer oil outlet)

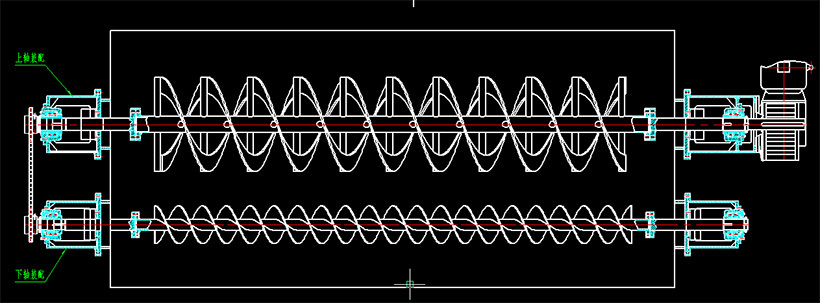

3. The upper and lower two layers of horizontal stirring are used in the tank, and there is no dead corner when stirring. (bottom picture)

4. Using tank weighing system, the amount of material added can be precisely controlled. Ensure the quality of rubber bitumen production.

5. The tank body is insulated with 10cm rock wool for energy saving.

6. The rubber bitumen pipeline has a circulation function.

7. The rubber powder adopts a lifting mechanism to avoid the dangerous environment of manual feeding.

8. The standby burner system can be turned on when the heating speed needs to be increased.

9. It adopts a large-flow wear-resistant rubber bitumen pump, which is durable.

Production process introduction

1. Heat the bitumen in the external bitumen storage tank with the thermal oil furnace of the rubber bitumen plant or other heat sources.

2. Plan this production volume and formula ratio. Calculate the required amount of bitumen and rubber powder.

3. Observe the weighing indicator and pump the required amount of bitumen into the mixing tank.

4. Open the heat-conducting oil valve and heat the bitumen to above 190℃. If you need to heat up quickly, you can turn on the burner.

5. The bitumen temperature is heated to the process temperature, and the stirring is started.

6. Use a hoist to lift the calculated rubber powder into the mixing tank.

7. After the rubber powder has been added, it will develop for 45-60 minutes to determine the viscosity of the rubber bitumen.

The viscosity of bitumen rubber meets local standards and can be exported.

Related products

Product Message

Wucheng Economic Development Zone, Dezhou, Shandong

Wucheng Economic Development Zone, Dezhou, Shandong +86-534-6692760

+86-534-6692760  info@bitumenequ.com

info@bitumenequ.com

liang@bitumenequ.com

liang@bitumenequ.com

Whatsapp

Whatsapp